Anyone who is familiar with power saws knows that the vast majority of them are used for making precise cuts to any number of workpieces.

But what about when there’s a need to merely tear something down, or cut it off and out of the way?

Reciprocating saws are the wrecking crew of saws. While a bit crude in nature, these powerful and incredibly versatile saws are invaluable to a wide range of contractors, and even some other professions as well.

Although many don’t consider reciprocating saws to be an essential tool for the DIY hobbyist who’s just starting out, we beg to differ. These saws are awesome. They have a ton of uses, and they are quite fun to use as well.

In this article, we’ll go over all the essential information one needs to know about reciprocating saws, which includes what they are best for, how they work, and pretty much every other detail you’ll need to be aware of before buying one.

Even Homer uses reciprocating saw.

So, with that said, let’s get right to it.

Over the years, I worked with more than 20 reciprocating saws, find out which one is my favorite.

What Is A Reciprocating Saw?

You’ve probably seen people on those home renovation television shows wielding a reciprocating saw around, especially during the demolition parts.

Like every other saw, the name gives plenty of insight into how it works. With a reciprocating saw, the ‘reciprocating’ part refers to how the blade moves, which in this case is back and forth.

A reciprocating saw moves like a good old-fashioned hand-powered hacksaw. In fact, that was the idea when these were first developed (more on that later).

This allows the user to hold the saw in place, while the blade does all the work, sawing back and forth either downwards or upwards.

The actual shape of the saw is very similar to a power drill, only with a blade sticking out of the front instead of drill bits.

This design and saw action limits the saw regarding making precision and angular cuts, but as for simple cuts to large materials, it can’t be beaten.

A Quick History Of The Reciprocating Saw

Reciprocating saws as we know them now have a relatively short history that started around the 1940s. But to first understand why they were invented, it’s best first to discuss a basic hacksaw.

Hacksaws are a simple and incredibly old style of the saw, and every single workshop will have one. You probably have one in your garage, even if you have no idea where it even came from.

These saws are very basic, usually consisting of a long blade, with a handle on top. To use one, you just place it over the workpiece and start sawing back and forth. You probably already know this.

For the longest time, these saws were the primary option for a variety of contractors, from plumbers to home builders. Thankfully, electricity became a thing, and power tools took off.

In 1949, Milwaukee Electric Tool Co. came out with a right angle saw that was very similar to the reciprocating saws we see now, only with the saw blade pointing downwards instead. These were marketed mainly towards plumbers, who need a way to saw pipes in tight spaces.

Did You Know?

In 1951, the first “Sawzall” was created, also by Milwaukee Electric Tool Co. This was the first power hacksaw that was mobile and ended up changing the saw game altogether.

This innovative saw was durable enough to take on the demands of several types of contracts, and also had changeable blades that let the user match it to certain materials. The Sawzall Recip Saw exploded in popularity soon after, for obvious reasons.

Now I should clarify a few things. There are some different names for reciprocating saws at this point, including “recipe saw,” “hognose,” and “Sawzall.” As for the latter, although Sawzall is, in fact, a brand name product, it’s become synonymous with reciprocating saws.

This is kind of like when someone calls any soda a “Coke,” even if it’s not, or when you hear someone refer to tissues as “Kleenex.” So, while Sawzall is an actual specific line of saws, it’s not uncommon to hear someone refer to a reciprocating saw as a Sawzall. Hope that clears things up.

Another term that has sprung up over the last few years is “Hackzall.” This is a generic way to refer to smaller reciprocating saws that are made to be even more portable and easier to use. For the most part, Sawzalls are the bigger of the two, making Hackzalls more popular for the average user.

Types Of Reciprocating Saws

Reciprocating saws are all similar for the most part, with the main differences being their size, and how they are powered. Still, they can be classified in a few different ways.

Corded Vs. Cordless

As with most power tools, you’ll find that reciprocating saws come in two different choices regarding power sources: corded, and cordless.

Cordless reciprocating saws operate off of battery power and are by far the most convenient. Battery packs are 9 or 12 volts, and the capacity varies among different models.

While cordless reciprocating saws are the most convenient, they do have a few drawbacks, mainly in regards to their power, and the fact that the batteries can run out. This can be dealt with by purchasing more powerful models and extra batteries, but you’ll pay more.

Corded reciprocating saws can be limited due to needing an electric power source nearby, but this usually isn’t an issue. With corded reciprocating saws, you get unlimited use without worrying about battery limitations, and they are often more powerful as well.

There are times when running a power cord to the saw isn’t always an option, or easy to do, so this is when a cordless reciprocating saw comes in handy. It’s all up to what your own needs and preferences are.

Mini Reciprocating Saws

Reciprocating saws come in a lot of different sizes, ranging from huge models that have 12-inch blade sizes, right down to smaller models that can be used with one hand if needed.

Mini reciprocating saws are the smallest of them all. These saws are not going to be able to take on heavy-duty tasks such as home construction and demolition, but they are great for when you need to cut a pipe in a tight space, or any other situation when space is going to be a hindrance.

Difference Between A Reciprocating Saw And Jigsaw

Jigsaws and reciprocating saws do have a few similarities. They are both handheld and have a flat saw blade that moves back and forth, but that’s pretty much where it ends.

Jigsaws are used for making intricate cuts in workpieces, such as curves. The blade of a jigsaw is much smaller and has finer teeth. This allows the user to carefully move it around a workpiece, performing both freehand cuts and guided cuts when necessary.

The blade on a jigsaw angles down, which is similar to angled saws that eventually became reciprocating saws when the blade was mounted horizontally. Jigsaws also have a shoe that allows the user to guide the saw along the top of a workpiece, making it easier to be more precise.

Reciprocating saws are the polar opposite of a saw that can make precise cuts. They are made for tearing things apart and performing crude trims on materials like pipes and boards. Even the most skilled saw operator could never use a reciprocating saw to make carefully angled cuts and such.

So, while reciprocating saws are operated in a freehand manner like jigsaws, they are for entirely different purposes.

Difference Between Reciprocating Saw And Scroll Saw

Like jigsaws, a scroll saw is used to make intricate and careful cuts in a workpiece. If you have rounded bedposts or any wooden furniture in your home that has curves, there’s a good chance it was cut using a scroll saw.

What a scroll saw is a mounted version of a jigsaw. The blade operation is similar, as is the size. The only difference is the saw is mounted in the middle of a flat table, so you can turn the saw on and guide a workpiece into the saw, usually by using a fence to hold it in place.

A reciprocating saw could not be any more different. It’s not mounted, it has a large blade, and you’d never think to use it for making curved cuts on furniture pieces, or anything else. Yes, you can freehand with it, but that’s going to be when you’re tearing down drywall or cutting studs.

Even if you could somehow mount a reciprocating saw to a table, you still wouldn’t get any results that are in any way acceptable. These two saws are complete opposites, but great for their intended purposes.

Reciprocating Saw Uses

Due to their simple design and exposed blade, reciprocating saws are great for a wide range of uses that span several scenarios. They truly are among the most versatile tools you’ll own.

Here’s some of the most common reciprocating saw uses.

Plumbing & HVAC

We’ll start with one of the main reasons these saws were developed in the first place. If you’ve ever had to do any plumbing work (or watched anyone do it,) you know that spaces can be incredibly tight. If you’re trying to work on a pipe, sometimes you only have a few inches.

Reciprocating saws can maneuver in tight spaces and then saw off pieces of pipe and whatever else, simply by aiming the blade right onto the pipe. With the squeezing of a trigger, you can quickly cut a pipe end off, without the need to move the saw around a lot.

This can be helpful for HVAC work as well, which often suffers from the same type of space limitations, especially when working inside of a wall, crawl space, or heater closet. Reciprocating saws can make quick work of drywall, and also trim down material pieces as needed too.

It’s safe to say that you’ll never encounter a plumber or HVAC specialist that doesn’t have at least a mini recipe saw in their toolbox.

Window Fitting

Window fitting and trim work can be incredibly frustrating, mainly because you have to get things exact.

If you’re an inch or two off, this word normal mean tearing the wall down and starting again, but if you have a reciprocating saw, you can trim down the frame area and try again.

The same goes when making the framing itself, or when trimming wayward studs and other materials during a project. Just power the saw on, aim the blade, and you can quickly remove obstructions or trim down accordingly.

This can save massive amounts of time and stress.

Construction

Construction is a pretty broad term, but reciprocating saws are very versatile, so their use is broad as well. For the most part, reciprocating saws are used for demolition during construction projects. This includes things like tearing down studs or even removing walls.

An example of this would be removing the drywall and studs on one side of the wall, without affecting the other side in another room. This comes in handy for times when the other room has already been completed or doesn’t need any wall work.

A reciprocating saw allows you to make calculated cuts into the wall and studs, carefully removing them and leaving an empty and clean workspace, with the other wall fully intact. This may not be as fun as taking a sledgehammer to a wall and busting all the way through, but the point remains.

Reciprocating saw use with construction projects also includes applications like removing door frames, cutting off screws and nails, and pretty much any other situation where you need to quickly saw something off or remove anything that’s in the way.

It’s hard to imagine doing demolition on any size project without the use of a reciprocating saw. This is where they shine, and the convenience and quickness are superior to any other tool.

Emergency Rescue Services

Something that may not initially come to mind with reciprocating saws is their usefulness with emergency services. Due to the protruding blade, a reciprocating saw is great for making crude cuts into materials when trying to gain access to someone or something inside.

This most commonly refers to rescues for anyone that’s trapped in a car after a wreck, but can also apply to anyone that’s been trapped in a home after a tornado, or any other significant weather event.

These saws can be used for fire rescue as well. So, just any scenario when there is no other way to besides making your improvised entrance. Again, highly invaluable, and demonstrates even more to the versatility of reciprocating saws.

Yard Work

Reciprocating saws can be a great ally for yard work tasks, especially when you need to do a little tree trimming, or just about anything else that’s growing.

The size and shape of a reciprocating saw’s blade make it perfect for cutting down small to moderately sized branches, and whatever else may need some trimming and cutting.

Anatomy Of Reciprocating Saw

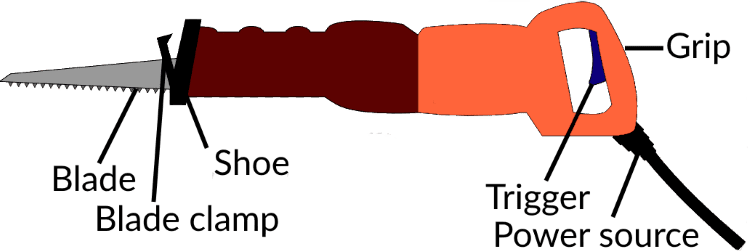

Reciprocating saws are fairly simple in design. Knowing the main components and parts can help you to understand better how they operate.

Blade

As you may have guessed, this is the part that does the actual cutting. The blade protrudes from the front of the saw and can be any number of different sizes, materials, and teeth design.

For most models, the blade can be quickly changed out when needed. Each blade has a special tip that connects to the inside of the drill, where it’s held in place by the clamp. The majority of reciprocating saws have a blade configuration that has it angled downwards slightly.

Shoe

The shoe is the flat portion positioned back from the tip of the blade. This shoe serves as a guide when cutting, and controls how much the blade can enter the material.

Most saws have a shoe that can be adjusted in several different ways, which includes the angle and depth. By manipulating the angle of the shoe, you can dictate the angle of which the blade makes contact when rating the shoe on the material.

The shoe’s depth is helpful for controlling how deep the blade goes into something. By pulling the shoe forward towards the blade’s tip, you can make shallow cuts, while moving it the other direction lets the blade cut deeper.

Blade Clamp

The blade clamp is used to hold the blade in place once you’ve loaded it onto the saw. This is often found under a small hatch towards the front of the saw.

Grip

The grip is where you place your second hand when holding the saw. This found towards the front and is usually positioned on the underside of the front portion. Nicer reciprocating saw models have soft grips that are also ergonomic for added comfort and control.

Trigger

The trigger is used to activate the saw’s blade. Reciprocating saws use a pressure sensitive trigger that lets you control how fast the blade moves in relation, which is often needed when first cutting, as you’ll start slowly and increase the blade’s speed as you cut.

Power Source/Button

A reciprocating saw’s power source is located towards the back and at the bottom. This is where the battery will be located, or where the cord will connect. The power or safety button is usually nearby.

Reciprocating Saw Blades 101

Different blade designs and materials can be used in correlation with what you’ll be cutting. Matching the appropriate blade to the corresponding material is recommended for best results.

- If you’re going to be cutting through metal pipes and nails, a fine-tooth blade that looks similar to a hacksaw is ideal.

- When cutting through the wood material, a coarse blade will work best.

- If you’re cutting through plaster and drywall, a very coarse blade is the best choice, as you don’t need precision, and you’ll save your finer blades.

- Plan on cutting stone, ceramic tile, and cast iron? A toothless blade coated with tungsten carbide abrasive grit will work wonders.

It’s worth mentioning that you don’t always have to be so rigid with your blade choice. For example, if you’re working on a roof that involves cutting through wood and nails, you can keep the same blade on and be just fine.

Blade Size

Most reciprocating saw blades are 6 inches in length, but you can also find smaller jig-saw-type blades, or even a bigger 12-inch blade if your saw is compatible.

Blade Maintenance

Reciprocating saw blades need to be changed as soon as you notice cutting being inhibited by the blade getting dull.

If you accidentally bend a blade, it can usually be hammered flat again. If the front of the blade is dull, but the rest is sharp, you can use tin snips to cut off the dull part.

You’ll have a shorter blade, but it’ll be perfectly fine to use. You can find short video guide for replacing reciprocating saw blade right above.

Reciprocating Saw Attachments

This is one of the best parts of a reciprocating saw. As if these weren’t already versatile enough, you can purchase some attachments to use in place of the blade that have absolutely nothing to do with sawing.

Since the part that causes the blade to reciprocate makes the same motion regardless of what it attached to it, you can find several different tools to use with the motor. Some of the more popular examples include grout removal tools, wire brushes, sponges, and scrapers.

When you buy a reciprocating saw, you’re buying a multi-use power tool.

How To Use A Reciprocating Saw?

Using a reciprocating saw is fairly simple. Here’s a quick step-by-step explanation:

Choose The Blade

The first step with a should always be the blade selection. You’ll need first to identify what the main material will be that you’re cutting, and then select the right blade for the task. If you’re unsure, just refer to the blade info up above.

Insert Blade

Now it’s time to put the blade into the saw and mount it. Fortunately, this is very easy. Simply insert the back end of the blade into the blade slot in the front of the saw, and make sure it’s all the way to where it can be secured by the blade clamp.

Now access your blade clamp, and use it to secure the blade in place firmly. Pull on the front end of the blade to make sure it’s secure before moving on.

Adjust The Shoe

This isn’t always necessary, but it’s always good to make sure you have the shoe set to where it needs to be before cutting. If you’re cutting into the especially hard material, you may want to angle the shoe more, so it gives the blade a sharper angle.

The adjustment can also be in regards to the blade depth. If you’re making freehand cuts on exposed nails and lumber pieces, this depth probably won’t matter/ However, if you’re cutting into a wall, and don’t want your blade going all the way through and out the other side, set the shoe to prevent it from doing so.

Squeeze The Trigger

As you probably already know, the trigger activates the blade. If you’ve got the right blade, angle, and shoe setting, you’re all ready to go. Squeeze the trigger to get the blade going. If you are cutting piping, or larger wood pieces, start the blade off slow and then increase speed after your little ways in.

Make The Cut

As you cut, be sure to apply even pressure in whatever direction you’re moving the blade, doing your best to keep it controlled throughout the cutting process — which hopefully doesn’t take more than a few seconds, ideally.

Reciprocating Saw Maintenance

This is another great aspect to reciprocating saws: they are extremely easy to maintain and care for. There’s no oil needed, no adjustments or calibrations, or any of that, just a little bit of caution, and some common sense.

As with any saw, it’s always best to make sure you keep it clean. When you’re done using it for the day, take a dry rag and wipe the saw’s body off, clearing out any debris or lingering sawdust that may have stuck.

- Use a breath of air can to clear out the insides periodically.

- If you have a fitted case for the saw, you’ll need to take the blade out, so you don’t risk accidentally snapping it off.

- It’s wise to check the power cord for any damage periodically.

- If you use batteries for your saw, never leave them in when not in use.

- As for the blades, follow the blade maintenance steps I listed further up in the article.

Follow these easy steps, and you’ll have a reciprocating saw that performs at its best for years to come.

Safety Tips For Reciprocating Saws

Any type of saw can be dangerous when mishandled. Here are some specific safety tips that will help ensure that you’re operating it safely.

- Always be especially careful when cutting near finished walls and floors, so you don’t cut through wires or pipes. Make sure you know where everything is.

- Always unplug the saw when changing blades putting on any accessories.

- Always wear safety glasses, no matter what you’re cutting. Hearing protection is strongly advised when cutting metal — it can get louder than you may think.

- When working on a ladder, be aware of the potential for a kickback from the saw if it gets stuck in the material you’re cutting. If you are cutting thick wood, it’s probably not a good idea to be high up on a ladder while you work.

- Reciprocating saw blades can get very hot, even after just a few seconds of cutting. Don’t touch the blade when you finish a cut, as you could end up with a pretty serious burn. Let it cool down first.

Conclusion

Are you on board with reciprocating saws now? You should be. As you can see, these saws embody versatility, and can easily operate as more than just a saw.

With one of these in your tool inventory, you can take on many tasks in a variety of scenarios. Whether you’re cutting out drywall, or cutting off a pesky tree limb, a reciprocating saw is up for it.

Thinking about buying a reciprocating saw? Be sure to check out our reciprocating saw buying guide before you do anything else. There, you’ll find our top picks for the best reciprocating saws on the market, spanning several different budgets and sizes.

Resources DoItYourself.com ProConstructionGuide.com RyobiTools.com ThisOldHouse.com FireEngineering.com FamilyHandyman.com