Ask any person to name a power saw, and it’s likely the first example that comes to mind will be a chainsaw.

There’s probably more than a few reasons for this, whether it’s due to seeing too many horror movies, or simply always having one around in the garage growing up.

We recently did a post on best american chainsaws. Check it out.

The point remains: chainsaws are popular, well-known, and in most cases, require little woodworking skill.

With that said, although chainsaws are mostly known as a destruction-oriented power saw, and often used for cutting stuff down, they are actually very versatile and have a wide range of capabilities that extend far beyond just chopping a wayward tree branch off.

Since chainsaws are almost always a part of the power tool inventory of the average homeowner or contractor, it’s important to know all the essentials about them, including their many uses, variances, and of course how to use them properly too.

So, if you’re looking for a quick guide to all the chainsaw basics, you’re in the right place.

Let’s get started by first establishing a clear definition of what a chainsaw actually is, and take it from there.

What is a Chainsaw?

At first glance, the definition of a chainsaw is fairly self-explanatory.

Indeed, a chainsaw really is a saw with a chain as a blade. Things are a little more complicated than that, however — but not much.

The official definition of a chainsaw is a portable, mechanical saw that uses a set of sharp saw teeth attached to a chain that runs along a guide bar. This setup creates a continuous motion of the teeth as the circle around the bar, resulting in a multi-sided cutting surface.

The chainsaw can be powered in a number of different ways, but the premise and operation is largely the same amongst all the different variations.

Unlike other power saws that are either attached to a table or mobile, a chainsaw’s cutting action is vastly different, with the lone exception being a band saw, which also uses a blade that runs in a continuous loop. (Other than that, band saws and chainsaws could not be any more different.)

Since the chain blade on a chainsaw is made up of thick teeth, a chainsaw is not ideal for any basic woodworking. There are some sawyers who are skilled enough to carve designs out of things like tree stumps, but this is a rare exception.

A Brief History of Chainsaws

You can trace the timeline of chainsaws back a few hundred years from where we are now — all the way to the early 1700s, actually.

While the original concept of a revolving chain as a cutting surface is hard to pin down, there was a device developed in 1830 by a German doctor named Bernhard Heine. His device was dubbed the osteotome, which had a chain with links of small cutting teeth that went around a guide bar, powered by a hand crank.

This tool was used to cut bone during surgeries, and was actually a play off of a larger and more cumbersome device conceived several years prior by two Scottish surgeons. While these tools were intended for surgeries, they would provide the basis of the modern chainsaws that are used today on wood.

The earliest known appearance of an actual chainsaw was in 1905, when Samuel J. Bens of San Francisco was granted a patent for what he dubbed an “endless chain saw.” He developed this saw in order to properly fell redwood trees, which was indeed a tall task.

The first actual portable chainsaw was patented by a Canadian named James Shand in 1918. His design was improved upon in 1933 by a German company, who was able to further refine its size and portability. Around this time, Andreas Stihl created an electric chainsaw for bucking, and then a gas-powered version a few years later.

After WWII, American company McCulloch came out with a two-person chainsaw that had an extended guide bar, which was effective for larger trees, but awkward to use. The first one-man chainsaw would not be developed until 1950.

From there, progress was very rapid, as chainsaws became smaller and lighter. This helped them become more of a mainstream tool for the average person, rather than a construction worker or lumberjack.

In 1964, Stihl came out with a product that had a built-in buffering system to reduce the heavy vibrations caused by the chain and engine. And in 1973, Husqvarna developed the automatic chain break, which is a lever that stops the chain after kickback, making it a lot safer.

In 1980, Husqvarna came out with a chainsaw using lightweight composite materials, followed by a chainsaw with multiple plastic components in 1983, making a chainsaw lighter, more affordable, and even more geared for the average user.

Innovation continues today, with light, energy-efficient chainsaws made for various uses, and with even more safety features and convenient maintenance aspects.

Modern Chainsaw Uses

Chainsaws have a long history, but their uses have remained largely the same over time.

Felling

The earliest use for chainsaws tended to revolve around the area of felling.

This process is the actual cutting down of a tree, often near the base of the trunk. As you can imagine, while the overall goal of felling is fairly simple, the process itself requires a large amount of skill and planning.

The earliest lumberjacks had to use two-person saws that were operated by pulling back and forth across the trunk using a longer version of a basic hacksaw. Axes could be used on smaller trees.

The development of commercialized chainsaws made this process a lot easier, more predictable, and allowed for more control as well.

Limbing

The limbing of a tree refers to the process of removing the limbs, leaving only the main part of the tree’s body. This is the main part of the timbering process that prepares a tree for being divided up and sold as lumber later on down the road.

As with felling, limbing a tree requires a lot of precision and planning when dealing with larger trees, as the limbing often takes places while the tree is still standing out of the ground, prior to being felled.

Before chainsaws, limbing was done using handsaws, which made the process more dangerous and took a lot more time.

Bucking

Bucking is often seen as the most crucial part of the timber process. This term refers to cutting up a felled and delimbed tree into logs.

While this sounds simple and somewhat easy, the way a tree body is bucked makes all the difference in what it can sell for, as the bucking must take into account the length of the lumber, its diameter, and any defects that are contained within.

Sawyers that specialize in providing precise bucking cuts are called buck sawyers, and chainsaws developed for bucking makes their lives a lot easier.

Pruning

Pruning is the process of removing certain parts of a tree, which is almost always the limbs. This is done on trees that are meant to be kept, rather than cut down or removed.

There are a lot of reasons for someone to prune a tree. The most common examples include helping to shape its appearance by getting rid of branches that seem out of place, or affect the desired aesthetic of the tree.

Pruning can also be used to get rid of dead or dying branches, which will help sustain the health and looks of the tree, and reduce the risk posed by any falling branches that could result from ignoring dead ones.

Firebreaks

A firebreak is a gap between vegetation that is used to slow or halt the progress of a wildfire. This is a common tactic with firefighters who are trying to impede large fires that have gotten out of control and are threatening to either increase in scope, or move through a certain area.

With firebreaks, timing is everything, so the ability to quickly chop down large swaths of trees is a huge advantage. This typically involves groups of firefighters or even military members swarming a certain area where the fire is heading, and then removing trees, bushes, and other vegetation so that the fire runs out of fuel and dies out when it reaches that point.

Cutting Firewood

One of the easiest and most general uses for a chainsaw is to cut up firewood. Whether it’s from trees you’ve cut down yourself, or wood that’s been salvaged or taken from another area, a chainsaw is a quick and easy way to cut up wood into the appropriate size for use in a fireplace or campfire.

This is a much better and less strenuous alternative to using a hand saw or axe to complete the process.

Other Uses

Aside from cutting wood in various capacities, chainsaws can also be used for construction. There are special types of chainsaws that can actually cut through concrete, making them popular for road construction and other similar infrastructure projects.

There is also a small group of talented sawyers that can use chainsaws for art. This is most often down with carving wood stumps, often into intricate designs, depictions of people, or animals.

This can be a popular solution for someone who has cut most of a tree down, but does not want to deal with the stump removal process of removing the roots from the ground as well. A skilled sawyer can carve a design into the stump, which is then used as a sort of natural decor.

There are also some who can use chainsaws to create ice sculptures.

Why You Need a Chainsaw

I’ve already touched on this a little, but the sheer versatility of a chainsaw makes it a must-have for almost any home or property owner. It’s useful for so many different tasks than can occasionally pop up every now and then, so it’s always best to have one on hand.

Most chainsaw owners will use one at some point to deal with tree limbs and large shrubs on their property. If you’re able to down a limb and then cut it up further yourself, you can save a ton of money when compared to hiring it out. Plus, you’ll have your own firewood if needed.

The same goes for cutting down bothersome shrubs and other growth around your property. If you have a lot of it to deal with, using other types of saws or manual saws can take several times longer than with a chainsaw.

There may also be times when you need to break something down in order to get rid of it.

Aside from being more convenient than hauling it off yourself, using a chainsaw to cut up something like an old desk or entertainment center that’s of no longer of any use can be a pretty fun few minutes. Just saying.

Add to this the fact that chainsaws can be relatively inexpensive, easy to maintain, and simple to use, and you can see why it’s a great choice to have one on hand when needed.

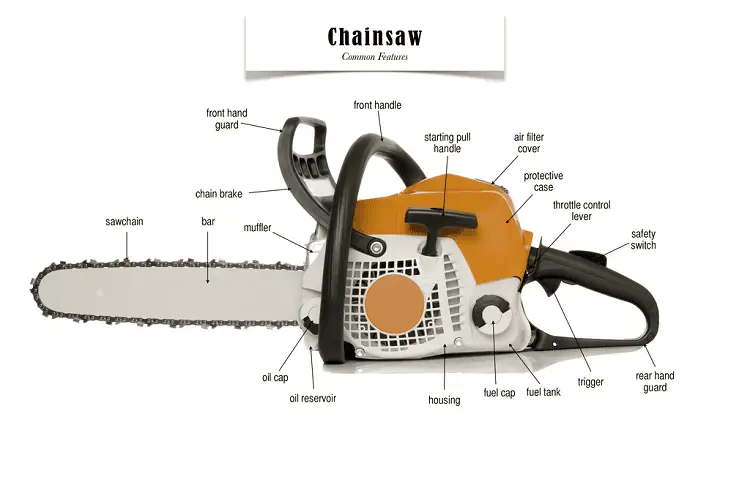

Anatomy of a Chainsaw

The best way to understand how a chainsaw works is to know all the parts that comprise it.

Engine

This is where it all starts, obviously. An engine is what allows the chainsaw to run on its own, rather than going back to the old days and using a hand crank to get the chain turning.

Engines come in a ton of different power amounts and types, some of which we’ll go over a little further below. Depending on the type, their power can be classified by wattage, horsepower, amps, etc.

While other components of the chainsaw are definitely important, the engine power is what determines the overall power and capabilities of what the chainsaw can actually do. For instance, a low power chainsaw will be fine for basic yard work, but not for felling large trees, and so on.

Drive Mechanism

The drive mechanism is a somewhat complicated system that determines when to engage the chain on the guide bar, causing it to turn and cut. This system usually involves a sprocket and a centrifugal clutch.

The clutch has three different tasks. When the saw is running idle below a certain rpm point, the chain won’t move. When the chain is moving, and the clutch senses the chain stopping by getting stuck, it will disengage. Third, if the clutch senses any kind of kickback, it will stop the drum immediately for safety reasons.

Guide Bar

The guide bar is the long, rounded extension that protrudes from the engine, and holds the chain. The guide bar contains an edged slot all the way around that is used to guide the chain and keep it in line.

The guide bar has a few different components and types:

- Gauge – This is the bottom part of the guide bar, and where the chain makes contact with lubrication, pulling it to the nose and spreading it throughout the chain as it travels.

- Grease Holes – As the name indicates, this is where you the grease gets pumped to from where you’ve filled it.

- Guide Slot – This is where the guide bar is attached to the saw body, usually with one or two thick screws that are run through the slot, and onto the clutch cover, where they are then tightened and secured.

Types of guide bars are as follows:

Laminated – These bars are comprised of several layers, helping reduce the front end weight of the saw.

Solid – Solid guide bars are made from solid steel, and used by professionals for heavy-duty sawing.

Safety – These bars are actually a subtype of laminated bars, and have a small sprocket on the nose to help reduce the amount of kickback. Most basic consumer-level chainsaws use this type of bar.

Chain

The chain on a chainsaw is what accomplishes all of the cutting, and does look quite similar to a bicycle chain — only with sharp cutting teeth spread throughout.

The chain rotates around the guide part at high speeds, creating a multi-sided cutting surface that can easily cut through sider objects like tree trunks and branches.

The teeth on the chain can vary greatly among types, making each type more apt at certain cuts and jobs. We’ll go over that in more detail further down.

Tensioning Mechanism

A crucial part of ensuring a properly functioning chainsaw (and ensuring safety) is to give the chain the proper tensioning required to do so. A chain should not be too tight on the bar, nor to loose. A tensioning mechanism is integrated into the guide bar in order to make quick adjustments as needed.

This is usually done by inserting a hexagonal key into the bar hole, and then turning it either left or right to loosen or tighten the chain.

Handle

Chainsaws require an external handle so that the saw can be controlled and applied to the object you’re cutting. These handles are usually found about the engine portion and are intended to behold by one hand, with your other hand on the back end controlling the throttle via the trigger.

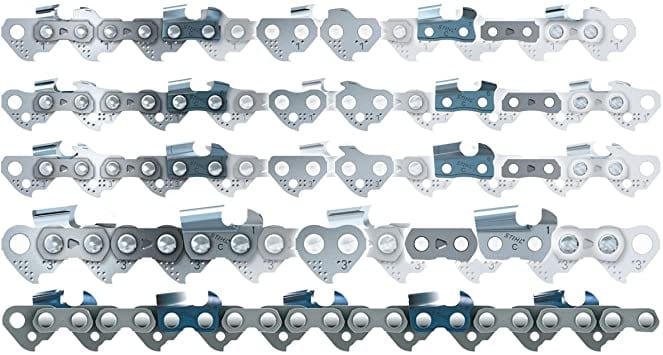

Types of Chainsaw Chains

All chainsaw chains use a similar idea for the most part, but there is a lot of variance as to how the cutting teeth are laid out, the length, shape, etc. This has led to the development over the years of chainsaw chains made for certain cutting tasks, materials, and so on.

Full-Chisel Chain

These chains are mainly used for softer woods, and feature square-cornered teeth. This configuration allows for a fast and clean cut, but if they’re used on harder woods, there is a higher potential for kickback.

You’ll rarely see full-chisel chains on consumer-level saws, as they are more appropriate for professionals.

Semi-Chisel chain

Semi-chisel chains are widely considered to be the most common, and most versatile.

A semi-chisel chain uses teeth with rounded corners between the top and side plates. They do not produce as “clean” of a cut as a full-chisel chain, but are a lot more durable, and better suited for sawing harder materials, or just a higher amount of sawing in general.

These chains do require some additional sharpening every now and then, but the average user can go a long time without having to do so. In addition to being the ideal all-around saw chain, semi-chisels also have a low amount of kickback.

if you want to sharpen your chainsaw you need a quality sharpener for your chainsaw .To read more about check this.

Low-Profile chain

Low profile chains are as they say: these chains sit lower into the guide bar, have lower teeth, and thus have a weaker cutting power. Most low-profile chains also have safety elements placed in between the teeth.

You’ll typically find low-profile chains on cheaper consumer-level chainsaws, or on chainsaws intended for the most novice of users. They are usually not appropriate for heavy use, or for cutting harder, thicker pieces of wood.

Chipper

A chipper chain is really not that much different from a semi-chisel chain. The actual blade teeth have a sort of question mark shape, as opposed to the “7” shape that a standard semi-chisel chain has. This lets the chain cut through denser and harder woods with ease, but at the expense of a clean cut.

Specialized Chains

Over time, several different types of non-standard chains have been developed for specific tasks. For instance, carbide-tipped chains with aggressive teeth patterns can be used for rescue work, such as cutting someone out of a collapsed building. Steel chains are common for work in frigid conditions.

What are the Different Chainsaw Power Sources?

Since this isn’t the early 1900s anymore, chainsaws have a few different power source options, as most any other power tools these days. Each one has some advantages and disadvantages.

Gas

A chainsaw that’s gas-powered typically uses a two-stroke combustion engine, not unlike one you’d find on a gas-powered trimmer. These engines often require oil to mixed with the gas, and also are usually the chainsaws that have the highest power and torque.

A gas-powered chainsaw is great if you want to be mobile, while also having an added amount of power that my be required for cutting down larger objects.

The downside is that you have to replenish the gas every so often, and also add oil to the engine. Gas engines are the most complicated, so there will be some added maintenance you’ll need to perform every so often as well.

Electric

Electric chainsaws come in many different forms, and in a lot of different power levels too. They plug into a standard extension cord, and give you instant chainsaw power as soon as you’re plugged in.

The great part about electric chainsaws is the fact that they’re always ready to go, no need for gas, oil, priming, or cord pulling. They are simple and easy to deal with, even for novice users who have little to no experience with power tools. Most economical chainsaws that still perform well are electric.

The drawback is also part of what makes these a popular choice: the cord. Since you have to worry about running a cord from a power source to your saw, you are somewhat limited as the top where you can use it. This probably won’t be an issue to someone using the saw in a basic front or backyard.

Battery/Rechargeable

A rarer power source type for chainsaws is a battery pack like you see with drills, various handheld saws, and some other forms of yard equipment. With a battery, you simply charge it up, pop it into your saw, and you’re ready to cut.

A battery chainsaw gives you the mobility of a gas-powered chainsaw, but without the complications and added expenses of a gas engine. This can be great for someone who needs to use the chainsaw away from a power source.

There are some disadvantages, however, mostly revolving around the power capacity of the battery. Most battery chainsaws are not as powerful as their electric or gas counterparts, and the ones that are can be expensive. Then there’s the whole constant recharging aspect as well.

Still, for some users, they are more than ideal.

Are Pole Saws a Type of Chainsaw?

Yes.

Some of you have likely seen a pole saw before. While there are a few different types, there are indeed pole saws that basically have a miniature chainsaw attached at the end, allowing you to reach high branches and vegetation and cut them without having to get on a stool or ladder.

We have plenty of information on pole saws, so be sure to check out our intro to pole saws, and our buying guide.

Important Chainsaw Aspects & Specs

When it comes time for you to start shopping for a chainsaw for your own use, there are some main areas you’ll need to be mindful of.

Size

The size of your chainsaw is going to be very indicative of its capacities. For instance, smaller chainsaws are clearly made for just removing limbs and cutting up smaller pieces of wood, while larger ones can be used for making firewood, or chopping down moderate-sized trees and shrubs.

It’s best to not get something too big for what you’re needing, and vice versa.

Pay attention to how long the guide bar is as well, since this shows the cutting capacity of the saw.

Power

If you’re going to be dealing with a lot of heavy cutting, make sure to shop for saws with larger engine power capacities, or else you’ll experience a lot of chain slips, getting the bar stuck, and wearing down for blades.

On the other hand, if you’re just doing some routine maintenance and light landscaping, a smaller engine size will do just fine. Trying to cut things beyond your saw’s power limits will result in more than a few issues.

Gas, Electric, or Battery?

I’ve covered this a bit, but it’s worth reiterating. If mobility is an issue, a gas or battery-powered saw is best. If you’re going to be staying around your yard within range of your extension cord, an electric saw will be much easier to use over the long term.

(Looking for the best chainsaws available? Head over to our buying guide after this, where we’ve picked five of the best chainsaws on the market, all for different needs and levels.)

Chainsaw Safety Tips

As with any saw, carefully following safety guidelines is absolutely crucial, or else you risk hurting yourself, someone else, or messing up whatever is around you. There are literally thousands of chainsaw-related injuries each year, and nearly every last one is avoidable.

These are giant mechanical saws after all, so don’t be foolish when using them.

Here are some quick chainsaw safety tips to help you out with that:

- Always read the owner’s manual before using. There is always bound to be some information specific to your chainsaw that can help you avoid accidents down the road.

- Know your limits. If you are unsure that you’re able to take on the project in front of you, it may be better to just hire a professional.

- Always wear protective gear, no matter what. This includes goggles or eye protection first and foremost, followed by gloves, hearing protection, and usually a hard hat as well.

- If you’re new to this, start by cutting some smaller objects. This can be smaller growths and trees around your property, or even a stray limb you’ve found somewhere. If all else fails, buy some firewood and practice cutting it up. This will give you a hands-on idea on how the saw will work.

- If possible, don’t cut alone. It’s best to have someone with you just in case you need help, or if there’s an accident.

- Do not cut wood someone else is holding. Just don’t. That’s how you end up on the wrong end of a YouTube video.

- Keep a first aid kit nearby, preferably in your toolbox, shed, or garage. If you don’t have one, get one.

- Always hold your chainsaw with two hands, no matter how strong you think you are, or how small the piece you’re cutting is. You’re not playing Leatherface in a horror movie.

- Don’t ever go climbing up a tree with a chainsaw — that’s for professionals. You’re much better off buying a pole saw, or hiring someone else to do it for you. And while we’re at it, don’t climb a ladder with one either.

- Don’t try to rush through things. Take your time, be steady, and see it through. Rushing can damage your saw, cause kickback, etc.

- Inspect your chainsaw before and after a task to make sure everything is where it should be, and working properly.

- Unless your saw is made specifically for doing so (it’s probably not,) don’t cut something using the tip of the chainsaw. You’re asking for a lot of things to go wrong.

- Don’t cut anything with the chainsaw while reaching over your head. Again, a lot of things can go wrong here, it’s never worth the risk.

- If possible, use a scabbard to transport your chainsaw around.

- Don’t refill your gas chainsaw until it’s cooled down.

- Keep your chainsaw out of the reach of children, unruly teenagers, and really anyone else you don’t trust using one outside of your supervision.

- Keep the bar and chain covered when not in use. This prevents accidents if it falls on something, and also protects the saw itself.

How to Use a Chainsaw

Already have a chainsaw and need to know how to get started using it?

Here’s a quick guide to get you up and running.

- Begin by examining your saw, and making sure there are no obvious defects, loose parts, etc. If it needs gas and oil, follow your manufacturer’s instructions to attain the proper level and mix.

- Remove the blade guard, and examine the chain’s tension. You should be able to barely lift the chain off the guide bar. Refer to your manual for the exact amount. If it’s too tight or too loose, use your hex tool to adjust the tensioning with a quick turn or two.

- Check the lubrication level of the saw, and add more lube if you’re low.

- Sit the saw in an area where you have clearance to pull the cord if it’s a gas-powered model. If not, you’re all set.

- Bring the saw over to what you’re cutting, and drive the saw downward onto it, with the tip pointed upwards just slightly. Let the chain make contact to begin the cut, and then slowly start pressing down through the wood.

- Follow through and cut all the way through the wood, maintaining the same angle. Do not overly force anything.

- Turn the saw off, reapply the blade guard, and either put the saw up, or move on to your next cutting task, and repeat. If you have more to saw, check the chain tension again.

Chainsaw Maintenance

In order to keep your chainsaw running smoothly, and avoiding any safety issues, there are a few things you’ll need to do regularly in terms of maintenance.

The main things you’ll need to watch out for are checking the guide bar and oil level frequently, followed by keeping the chainsaw as clean as possible and tending to the chain to keep it sharp in between uses.

Sharpening

Sharpening seems like a hard task, but it’s really not at all. Aside from that, it actually makes your job easier, since dull chainsaws have difficulty cutting.

- To sharpen, begin by putting the chainsaw in a vise, or something else to secure it and keep it held down.

- Turn the chain brake on to keep it in place. Using a chainsaw teeth sharpener, position the file so that the arrows are pointing towards the nose of the guide bar.

- Start filing the teeth at a right angle to the rollers, and file every other tooth using a smooth and firm stroke, making sure each one is even. Move onto the next tooth.

- After you’ve done all the teeth facing one direction, turn the saw around and repeat the same process for the remaining teeth.

Cleaning

Keeping your chainsaw clean isn’t really about looks, it’s about keeping dirt and debris out of the moving parts, and your engine.

- Aside from wiping the outside of the saw down with a dry rag after uses, you’ll also need to clean the guide bar by taking a thin piece of wood or metal and using it as a scoop to remove debris stuck in the tracks.

- If you have a gas engine, it’s also important to wash the air filter periodically, clear out cooling fan vents, and remove debris from air intake slots.

- Other areas to be mindful of include checking the throttle control to ensure it’s not getting stuck when you let off the trigger and making sure the chain catcher and chain brake are working as they should.

As always, keep an eye on the lubricant level, even in between jobs that same day.

Conclusion

Chainsaws are probably the most accessible and recognized power saws on the market, yet it’s surprising how little many consumers know about what they’re actually for, and how to use them right. Hopefully, you have a much better idea after reading through all this.

As I mentioned earlier, chainsaws are a crucial tool to keep in your garage or shed, and I believe every home or property owner should have one.

There, you’ll find our top five chainsaw picks across several budgets and types, along with some helpful buying advice to make sure you end up with the perfect chainsaw for your needs.