When it comes to essential power tools for the serious contractor or DIY enthusiast, a circular saw is an absolute must in every way.

These versatile saws are considered the pillar of electric-powered saws, and offers uses for everything from major construction projects, to simple tasks in and around the home.

Although relatively simple, a circular saw is capable of handling a number of different materials that go well beyond just wood. Depending on the blades and types you’re using, these saws can handle everything from masonry to metal.

Are you a little unfamiliar with the capabilities, design, and uses of circular saws?

You’re not alone. In this guide, we’ll walk you through all of the vital information one needs to know in order to have a better grasp as to how these saws work, and how they can benefit you, regardless of your abilities.

If you’re in the market for a circular saw, but feel like you’re a little unprepared, we’ve got you covered. Read on to learn all you need to know.

Contents

What Is A Circular Saw?

By its most simple definition, a circular saw is any power-saw that utilizes a toothed or abrasive disc/blade that is able to cut by using a rotary motion that spins around an arbor.

The concept is simple in nature, but there are a lot of moving parts involved within.

Circular saws can be used for cutting numerous materials, including wood, masonry, plastic, or metals. These saws can be either hand-held, or affixed to some sort of machine, and range in size, but not by much.

When using the term “circular saw” in regards to woodworking, it refers only to the hand-held type although table saw and chop saws are still common forms you’ll encounter. The name “Skil saw” has now become a generic term for any conventional hand-held circular saws.

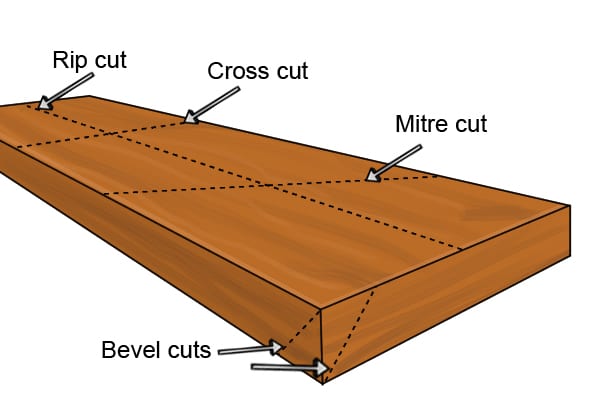

Although circular saws are able to handle different materials when cutting, it is all dependent on the type of blade being used for each material. Blades designed for cutting wood are specifically made to for make rip-cuts, crosscuts, or a combination of both.

The vast majority of circular saws are powered by some sort of electricity, but there are some gasoline-powered versions, and even some hydraulic powered ones as well. For the most part, the average contractor or homeowner uses an electric powered version, usually with a cord.

Circular Saw History

Circular saws have a long and storied history that dates back to the late 18th century, when they were first invented as rip-saws, being used to convert logs into lumber at sawmills.

Before circular saws came into being, logs were sawn by hand using a either a pit saw, or powered saws using an up-and-down saw involving a reciprocating motion. Although effective, these saws were not nearly as efficient as they should be for the type of work. On the video below you can found one example of this historic circular saws.

This led to the invention of the circular saw, as it cuts faster because the teeth are in constant motion while turning, rather than the back-and-forth operation of other saws. The sound of the circular saw earned it the nickname buzz-saw do to the constant buzzing sound it made while cutting through wood.

Sawmills first used these newer, smaller diameter circular saws to actually resaw dimension lumber such as lath and wall studs that were used for edging boards and such.

As the technology improved and progressed, larger diameter saw blades began to be used for the head saws while they cut through clapboards.

Now, going back to the actual inventor the first functional circular saw, there are a wide number of claims.

The most significant claims include:

So who was the first person to rightfully invent the circular saw?

Based off the info above, it’s very likely that many people came up with the idea on their own, as the need for a more efficient and agile sawing method was not restricted to just one part of the world.

Why Is Circular Saw Must Have For Every Craftsman And DIY Enthusiast?

This is actually quite simple. Every craftsman, whether you’re a professional, or just someone who prefers to handle many home projects on your own, there is a constant need to cut things.

It’s an unavoidable need. Pieces of wood, metal, plastic, even stone — none of these usually arrive in the ideal size or shape for what you’re needing.

And if you’re familiar with home projects, you know that it’s all about precision, especially when you’re building structures, or smaller things like cabinet drawers and such.

Now, unless you’re into taking the caveman approach and using a handsaw or everything, you’re going to want a saw that is fast, efficient, and precise, but also has a good amount of portability and versatility. That would be a circular saw. Specifically, a hand version.

The size and portability is not the only reason you need a circular saw, it’s the type of cuts it can make as well.

Circular saws can make cross-cuts (across the wood rain,) rip cuts (with the grain) and the lesser used plunge cuts (starting the blade above the item and lowering it down into it.) The ability to make all of these cuts makes the circular saw the monkey wrench of cutting tools.

A conventional circular saw also doesn’t require a lot of space, and you always have the option to bring it around with you, whether you’re standing in your kid’s half-assembled treehouse, or sitting on your roof.

So, a circular saw can handle large and small tasks, and doesn’t require a ton of expertise or additional equipment to operate. Even if you don’t have something like a jigsaw or miter saw in your workshop, a circular saw should be a non-optional saw. Always start here.

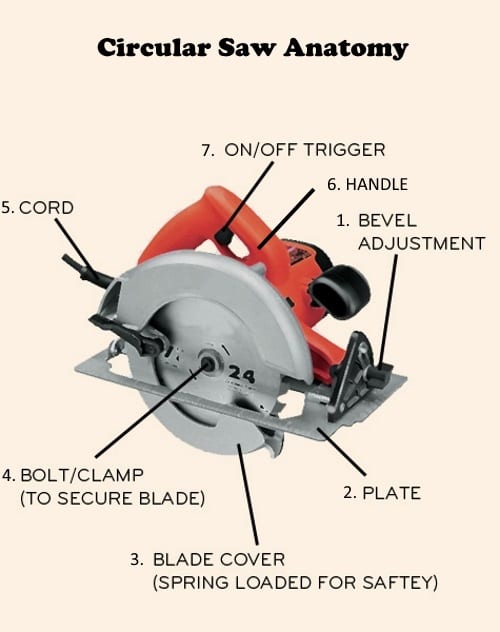

Anatomy Of Circular Saw

To better understand how a circular saw works, it’s best to be informed about all the various parts, and what they are for.

Bevel Adjustment

The bevel adjustment is located towards the front of the saw, and a little off to the side. It is responsible for adjusting the bevel angle when cutting, which allows the user to make angles in the object with ease. This is often down with a knob attached to the plate.

Plate

The plate is located in the middle of the saw, and surrounds it on each side. The plate allows the user to sit the saw down onto an object while sawing, helping to keep it steady and level. This can also act as a guide for the saw when moving it along the object.

Blade Cover

The blade cover fits snugly over the blade on the top and bottom, with a small opening in the front of the blade where it’s designed to conduct the cutting.

As you may have guessed, this offers protection from accidental contact from the blade, whether that is in regards to the user, or to other objects nearby.

The cover also prevents debris from flying all over the place, kind of like a mudflap would offer for a bike tire.

In this great short video, our friends from Expertvillage.com will show you how to set bevel on your circular saw, don’t worry, it is 20 seconds job and you are ready for cut, and we all love to cut 🙂

Bolt Clamp

The bolt clamp is used to secure the blade to the saw’s body.

Blade

The actual blade of the saw is responsible for all the cutting. The blade needs to be a specific size for the saw’s body, and can be changed out by removing the bolt clamp. There are different saw blades for different materials, which we’ll go over below.

Cord

Fairly self-explanatory. If you have a corded saw, the cord will be located on the back, and often removable for storage purposes.

Handle

The handle is used to maneuver the saw when in use. Higher-end models will have ergonomic designs that make it a little more comfortable to hold while sawing, while also offering a little more stability as well.

Power Switch and Trigger

This turns the saw on and off, which is pretty convenient when using a saw for obvious reasons. Once powered on, the saw’s can be turned on and off by using the trigger underneath the handle. Some circular saws come with a electrical brake.

Circular Saw Types

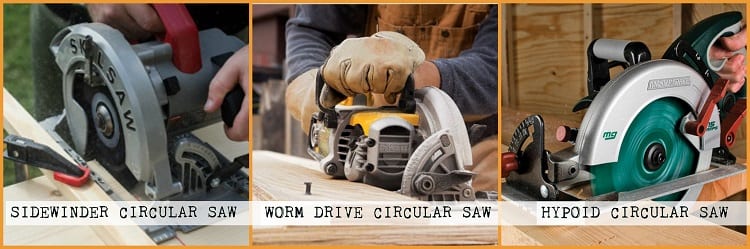

There are a number of different circular saws available. We’ll cover the three main ones that are common for home and craftsman use.

Sidewinder

Sometimes referred to as an in-line saw, a sidewinder is arguably the most popular circular saw. The motor is mounted on the side of the saw, making it more compact.

This also allows the motor to rest on the solid workpiece, instead of the cutoff portion.

The sidewinder usually weighs a lot less than the other types of circular saws, so it’s great for cutting materials overhead. It can also spin at a higher speed since the motor is right by the blade.

Sidewinder saws are widely available as cordless models, and often lack the need to be oiled regularly as well. So, in regards convenience, weight, speed, and maintenance, they are the most ideal.

Worm Drive

With a worm drive, the saw’s motor is mounted toward the back of the tool, which makes it longer and more narrow, than a sidewinder.

The saw’s cutting power is transferred to the blade by two gears positioned at a 90-degree angles. This configuration does decrease the blade’s speed, but on the flip side, it does provide more torque.

Why is this handy?

The length of the saw makes it easier to cut wider boards, and also makes plunge-cutting easier. This saw does involve some added maintenance, including adding oil every now and then.

Hypoid

These have a similar look to worm drive saws, which results in them being mistaken from time to time. While similar in looks, hypoid saws have a different transmission and gearbox.

The name refers to the hypoid gear the saw uses, which is a type of spiral bevel gear that’s axis is not in-line with the axis of a meshing gear. The hypoid design improves blade contact, while improving power and efficiency, and also reducing motor size and noise.

Hypoid saws have a sealed motor system, so there is no need to add oil. Like a rom drive saw, hypoid saws are heavier, and better for cutting long pieces of wood, and especially helpful if the wood is wet or damp.

So to recapitulate we analyzed pros and cons of these 3 types and summarized it in table below.

|

Sidewinder |

Worm Drive |

Hypoid | |

|---|---|---|---|

|

Best for: |

DIY Woodworking |

Plunge cutting |

Cutting wet wood |

|

Pros: |

Portability, versatility |

Reach, power |

Power, adjustability |

|

Cons: |

Lack of power for deeper cuts. |

Maintenance |

Weight, price |

Circular Saw Blades

As we brought up earlier, there are a number of different saw blade types that each correspond to what they are made to cut.

Common Wood Blades

Ripping Saw blades – These blades are made primarily to get a smooth, clean and safe cut when ripping wood or cutting in the same direction along with the wood grain.

They have a limited number of large and straight teeth, allowing the dust from the cut to be removed more efficiently. A quality one will slice through almost every type of wood with ease.

Combination Saw blades – The most common type of blades, these are designed to cut both rips and crosscuts. A combination blade allows one to cut in both directions, and come with a variety of tooth counts.

Combination saw blades are great for circular saws that are lacking power. Loss of material is minimal. The higher the number of teeth, the smoother the cut.

They are also called all purpose saw blades so it’s no wonder that they are almost on every circular saw out there.

Crosscut Saw blades – These blades achieve a smooth, clean and safe cut when cutting perpendicular to the wood grain. Crosscut blades use kerfed teeth, which means they alternate from leaning left and leaning right.

Most crosscut saw blades are carbide tipped and you will be forced to change it faster than other two types of woodworking saw blades.

So use it with precaution.

Other Blades

Masonry – A masonry cutting blade is designed for cutting through hard materials such as concrete and natural stone. Masonry blades do not have any teeth, and are made of fiberglass-reinforced silicone carbide abrasive, which is the same material commonly found in sandpaper.

There are two different types of masonry blades: a more coarse version for softer materials like concrete block, brick, and limestone, and another for harder materials like concrete, marble, granite, and all types of glazed ceramic tile.

Metal Cutting Blades – Metal cutting abrasive blades are also toothless, and often have heat expansion slots cut into the blade that are designed dissipate the heat created when cutting metal.

These blades can be used to cut through copper tubing, aluminum flashing, aluminum siding, and most other types of ferrous and non-ferrous metals, including brass, bronze, and light-gauge sheet steel.

High-Speed Steel – These blades are harder than steel blades, and can stay sharper for an extended period of time.

Carbide-Tipped (TCT Blades) – Carbide-tipped blades are generally made with boron, calcium and/or silicon, or metals such as cobalt, tantalum, titanium, or tungsten. This makes them extremely hard, and able to stand up to other hard materials with ease.

These blades are great for cutting effortlessly through plywood, aluminum, plastic and melamine, and are very popular among by cabinet makers and sign makers, since the blades can cut through acrylic as well.

Tile-Cutters – blades are specially designed for cutting ceramic tile. Higher-end tile-cutting blades have diamond tips.

Circular Saw Power Options

When dealing with standard circular saws, you have two main choices.

Cordless

Cordless circular saws are obviously the most convenient, as they don’t require you to stay around a power source.

These are best for cutting wood and wood products because of the limited charge of the batteries. Other materials require more power and can wear the batteries down faster. They can work when cutting harder materials, but the power needed drains batteries quickly.

Corded

Circular saws with cords don’t depend on batteries for power, making them better-equipped to handle long sawing jobs, and/or tougher materials. Corded saws come in a lot of different sizes, with the most common being 7-1/4 inches.

Keep in mind that corded circular saws need a compatible extension cord, so be sure to follow the manufacturer’s guidelines.

5 Most Important Circular Saw Features

Without electrical brake, circular saw will keep spinning up to 15 seconds.

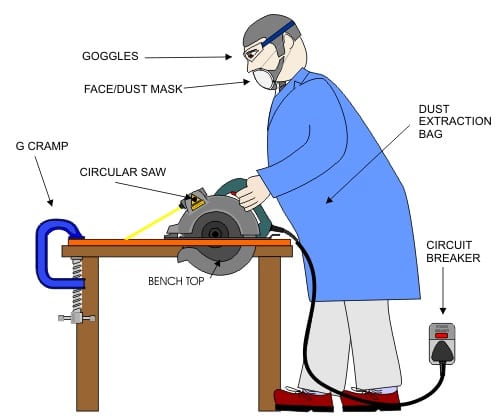

Circular Saw Safety Tips

Saws are used for cutting, which gives them an aspect of danger that needs to be avoided as best you can. In order to be safe and successful with circular saws, there are a number of tips you should follow to ensure everything goes well, and without incident.

Here are some things to make sure of before you begin sawing:

Tips for during the saw’s use:

Here’s some things to NOT do while sawing:

- times-rectangle

- times-rectangle

- times-rectangle

How To Use A Circular Saw

The majority of circular saws are sidewinders, so the blade is mounted on the right-hand side of the saw’s motor. If you’re right-handed, you will need to lean over the saw to be able to see the cut line.

If you are using a worm drive saw, the blade is often mounted on the left-hand side of the saw’s body, so you’ll have easier visibility of the blade as it cuts.

Now before you start cutting, position the material being cut onto a stable surface, ensuring that the item is secure and that the portion being cut off will not bind as the cut is proceeding.

Using A Guide While Cutting

When making a cut, use a straight edge for long cuts, or a combination square for short cuts as a guide.

To use a square, align the saw blade with the cut line, and then position a combination square with the edge firmly against the far edge of the cut piece, perpendicular to the edge of the square that’s lined up with the side of the saw’s base.

As you start to cut, keep the edge of the saw’s base pressed against the side of the square, which will keep your cut straight.

If you’re making longer cuts on plywood, use a metal straightedge and a pair of clamps to hold the straight edge in place — you can use it as a guide for the circular saw.

After you’re done with the cut, release the saw’s trigger while keeping the base of the saw in contact with the cut piece until the saw blade is no longer turning. Once the blade is done, you can set the saw down. Be careful with the cord.

Free-Handing A Cut

There may be times when you need to free-hand a cut without any kind of guide.

Keep in mind that this does not mean that you can simply hold a board in one hand, and cut with the other. This is a good way to send the board flying, or lose control of the saw.

Free-handing is best with worm drive saws. Place the board flat across the two sawhorses, and then align the base of his worm drive saw evenly with the top of the 2×4 inches to make the cut, allowing the cutoff to fall away. This is a lot safer than the alternative.

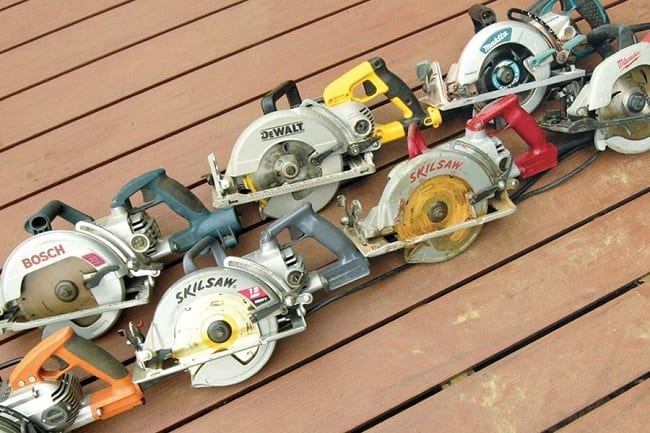

Popular Circular Saw Manufacturers

Although there are a ton of manufacturers out there making circular saws, the four listed below are among the most popular, trusted, and well-know…and for good reason.

This isn’t to say that other companies are incapable of making quality products, but it’s hard to go wrong with and of these.

DeWalt

DeWalt is easily one of the most recognized power tool names in the world, and a preferred brand by countless professionals in a variety of industries. DeWalt has a long history with saw products, so it’s no wonder they are so relied upon today.

The original company was started in 1923 by Raymond E. DeWalt, who was actually the inventor of the radial arm saw. The company grew rapidly and was reorganized and re-incorporated in 1947 as DeWalt Inc.

The company was eventually bought by American Machine & Foundry Co., Inc., who later sold it to Black & Decker in 1960. Today, DeWalt continues to put out some of the best circular saws on the market, while continuing to implement new technologies while keeping prices manageable.

Porter Cable

Porter Cable circular saws are another favorite among professionals and hobbyist alike, and the company actually has strong ties with DeWalt.

Known for pioneering the portable belt sander, helical-drive circular saw, and portable band saw, Porter Cable is a subsidiary of Stanley Black & Decker, who owns DeWalt. The company was originally was founded in 1906, when they began to focus on power tools such as lathes.

Porter-Cable began to develop a niche in portable electric power tools in 1926 with the portable electric belt sander, called the Take-About Sander. In 1929, the company invented the helical-drive circular saw, a compact, lightweight design that is still the most widely used circular saw design in production today.

Makita

Makita is a Japanese-based power tool company that specializes in saws. The company was founded in March 1915, by Saburo Makita in Nagoya, Aichi, and originally sold repairing lighting equipment, motors, and transformers.

Over the next few decades, Makita became renown for their line of power drills, before eventually re-focusing their efforts onto various saw products. Makita circular saws are beloved for their versatility and affordability.

Ryobi

Ryobi is another example of a prominent Japanese circular saw manufacturer. The company was founded in 1943, and began production of power tools in 1968.

The majority of Ryobi circular saws are geared towards DIY enthusiasts who want high-end performance, but without spending the money they would with commercial models.

Circular Saw Maintenance And Cleaning

Circular saws are actually quite simple to care for, and most of it revolves around care for the blade.

As for the actual saw body, it’s best to wipe it down after every use, and be mindful of any sawdust or debris that has gotten wedged in anywhere. Air cans that are commonly used for cleaning computer keyboards are effective for removing buildup.

The saw blades should be cleaned regularly. To do this, first remove the blade, and then wipe it down using a paper towel or damp rag.

If there is excessive buildup, you can use a citrus-based degreaser, or something like Simple Green. Wipe the blade down while being mindful of the teeth, pat dry, and allow it to air out before mounting it back on the saw body.

Conclusion

Circular saws aren’t the most complicated tools, but they do require a bit of practice to master, and it certainly helps to know as much about them as you can so you can not only use them safely, but get the most out of them.

As one of the most useful and versatile power tools, a circular saw is one of the most important purchases you can make. Ready to move towards picking out your new circular saw? Be sure to check out our buying guide for the best circular saws available for a variety of budgets, and also our in-depth product reviews as well.

Resources SafetyCulture.com.au AskToolTalk.com Ronin-Group.org FamilyHandyman.com CCOHS.ca